http://www.industrialmanuals.com/komatsu-forklift-series-forklift-truck-operations-maintenance-manual-p-2063.php

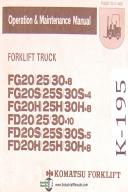

Komatsu Forklift FG & FD Series, Forklift Truck, Operations & Maintenance Manual Year (1987)

This Manual Covers Models:

FG Series

FD

FG20S25S/30S-4

FG20/25/30-8

FG20H/25H/30H-8

FD20/25/30-10

FD20S/25S/30S-5

FD20H/25H/30H-8

This Manual Includes:Foreword

Breaking in your new Machine

Check Before Starting

Periodic Maintenance

This Manual Covers Models:

FG Series

FD

FG20S25S/30S-4

FG20/25/30-8

FG20H/25H/30H-8

FD20/25/30-10

FD20S/25S/30S-5

FD20H/25H/30H-8

This Manual Includes:Foreword

Breaking in your new Machine

Check Before Starting

Periodic Maintenance

Periodic Replacement of Consumable Parts

Maintenance Table Replacement and Check

Service Data

Lubrication Chart

Handling Machine in Extremely Hot Places

Maintenance Table Replacement and Check

Service Data

Lubrication Chart

Handling Machine in Extremely Hot Places

Cold Weather Operation

Storage

Fuel and Lubricants

Storage

Fuel and Lubricants

Wiring Diagram

Before Operating Forklift

General Locations

Instruments and Controls

Operating Your MachineThis Manual Has 66 Printed Pages.

Year 1987

Before Operating Forklift

General Locations

Instruments and Controls

Operating Your MachineThis Manual Has 66 Printed Pages.

Year 1987